This year’s electrical fire safety week takes place from the 9th November and acts as a valuable reminder to businesses about the fire risks associated with electrical equipment.

While the potential for hazards with some types of equipment is obvious, we’ll bet there are plenty of small portable appliances lying around your workplace, like kettles and microwaves, which look innocent but could cause trouble and set off your fire alarm. And given the time of year, it’s likely that portable heaters are making an appearance too as they re-emerge from the back of the storeroom, get dusted down and plugged in without much thought about their condition. Heaters offer certain temptations too; we’ve seen people drying wet coats on them and using them close to combustible materials like curtains or paper (you should always make sure they’re at least a metre away). And it’s easy to forget one is on and leave it unattended or, far worse, leave it on overnight.

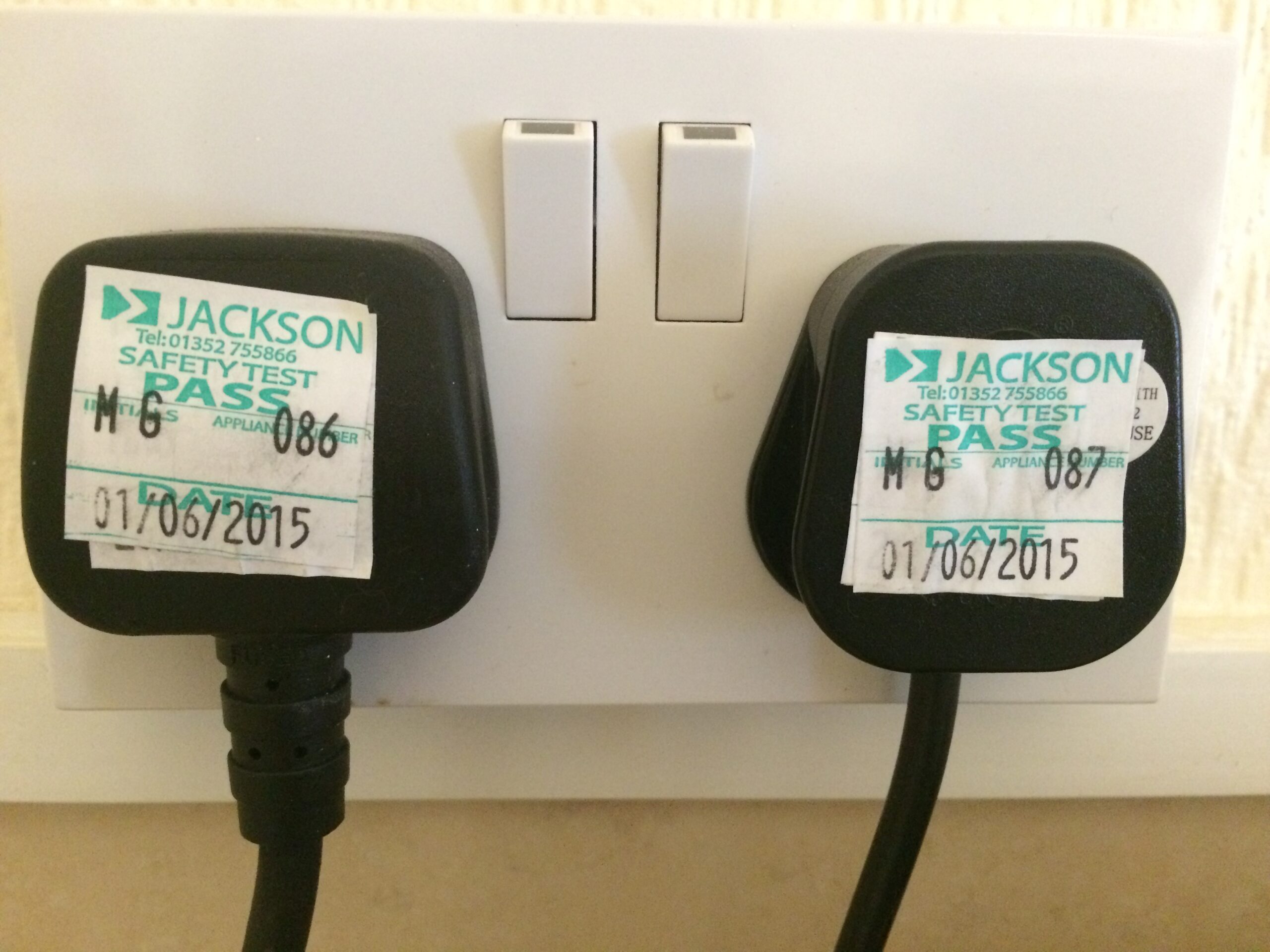

Even when people are using equipment sensibly, and are aware of the dangers of overloading sockets that isn’t necessarily enough. See our article on electrical socket safety. You’ll probably know the importance of carrying out visual checks – either simple user checks or a more formal inspection - to make sure appliances aren’t damaged before they’re used. But sometimes those checks alone aren’t enough to know quite how safe an appliance is. That’s when portable appliance testing can be a big help.

Using a risk based approach to keep portable appliances safe

- Consider the type of equipment, the environment it’s in and how it’s used. The more frequently something’s used, the greater the wear and tear. That can increase the chances of it getting damaged and becoming a fire risk.

- You aren’t legally obliged to label equipment or keep records for equipment that’s been PAT tested or visually inspected. But as a management tool it’s far easier if you have some kind of record to monitor what has and hasn’t been checked. It’s also useful to be able to demonstrate you have a system if you ever had to prove you were fulfilling your legal obligations. And if you have 5 or more employees, don’t forget you need to record your fire risk assessments – and this information will be helpful.

- While in theory it should be ok to assume new equipment doesn’t need any checks, it’s always a good idea to do a quick visual inspection first to make sure there are no obvious problems.